Too much inventory means that the company is taking on unnecessary holding costs while also running the risk of increased costs due to damaged goods. On the other hand, too little inventory can lead to stock-outs which will cause you to lose sales. Having to reorder goods frequently also racks up transportation costs.By calculating EOQ, a business can determine when an order is to be placed and how much is to be ordered. This allows the company to make strides towards being as cost-efficient as possible while ensuring that production and sales continuity is guaranteed. Without it, companies will tend to hold too much inventory during periods of low demand, while also holding too little inventory in periods of high demand. The Economic Order Quantity (EOQ) formula is a cornerstone of efficient inventory management.

Economic Order Quantity (EOQ): Definition and Formula

Using EOQ supply chain calculations is only effective if you can use reliable data. When you use the economic order quantity model can help you cut down on dead stock and obsolete or expired products. By calculating the optimal order quantity of each item, you will be more likely to sell it well before its best-by date.

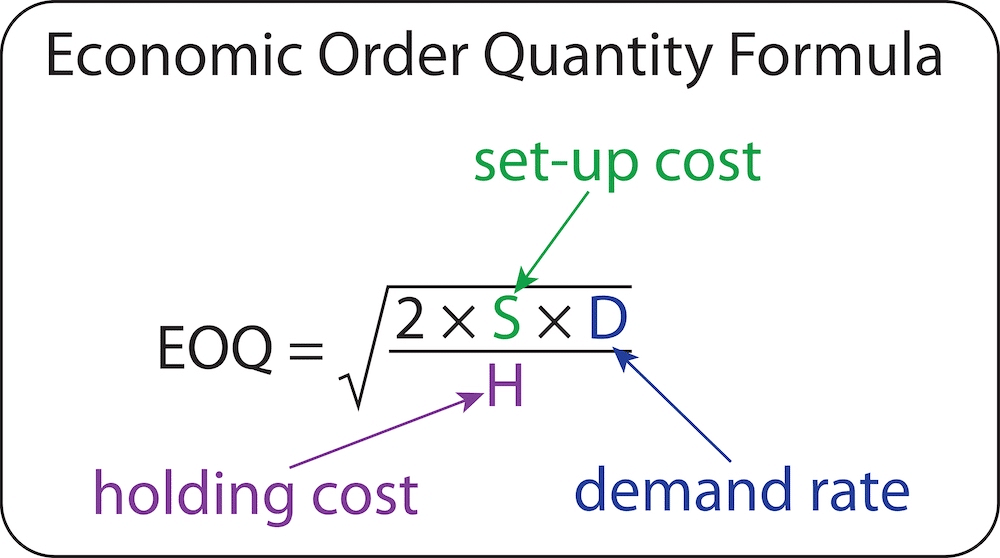

Setup Costs (S)

Economic Order Quantity (EOQ) is an inventory management method that determines the optimal quantity of items to order to minimize the total cost of ordering and holding inventory. Since 2016, Qoblex has been the trusted online platform for small and medium-sized enterprises (SMEs), offering tailored solutions to simplify the operational challenges of growing businesses. With a diverse global team, Qoblex serves a customer base in over 40 countries, making it a reliable partner for businesses worldwide. Critics have argued that the assumptions of constant demand and fixed cost levels are a limitation of the EOQ model.

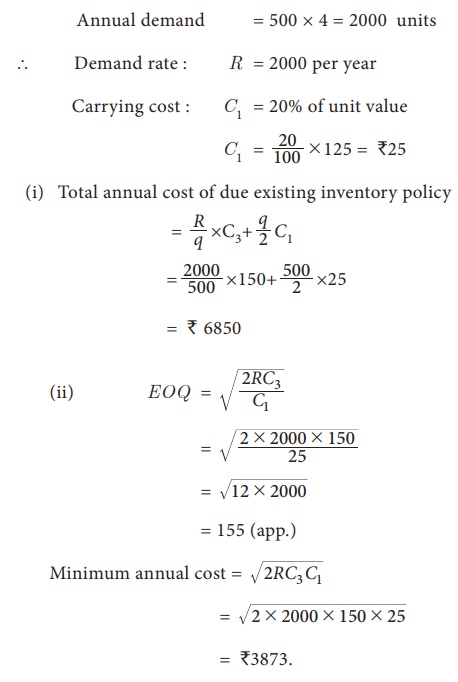

How To Calculate EOQ With an Example

Now, the example we used above is pretty simplistic—and unfortunately, calculating real-life inventory costs is rarely that easy. Applying EOQ calculations to your inventory management can be a huge cost saver. But it also involves doing a fair bit of math—making it a relatively difficult model to implement if you’re tracking your inventory manually. Economic order quantity (EOQ) is the theoretically ideal quantity of goods that a firm should purchase that minimizes its inventory costs. Carrying cost is calculated based on the insurance premium, depreciation, obsolescence, storage, preservation costs, and interest on value of stock held, including that of handling and other allied costs.

The Economic Order Quantity determines the inventory reorder point of a company. By doing so, the company continues to fill orders and does not run out of inventory. There is also revenue lost if the company can not fill an order due to insufficient inventory. Additionally, a lower stockout rate achieved through EOQ optimization enhances customer satisfaction and order fulfillment.

- Also, as the number of orders decreases, the ordering cost decreases but the holding cost increases.

- If an item doesn’t have a known carrying cost, then the eoq calculation can be modified.

- By inputting data on demand, ordering cost, and holding cost, businesses can use the EOQ model to determine the optimal order quantity for a product, reducing their costs and improving their profitability.

- The quantity of stock should allow the business to meet customer demand and minimize costs at the same time.

- Plus, you can manage inventory carrying costs efficiently and improve order fulfillment speed – all these contribute to meeting customer demands and enhancing customer satisfaction.

- They include Zoho Inventory EOQ Calculator, QuickBooks EOQ Calculator, and Omni Calculator.Omni Calculator is the best EOQ formula calculator.

This illustrates that the economic order quantity is always in the best interests of the firm. There are times when the cost of estimation and calculation exceeds the savings made by buying the objective of the economic order quantity is to minimize the total: that quantity. It keeps the rate of order at a normalized level that will be beneficial to the business. The amount of money spent on inventory storage becomes lesser and more affordable.

Ordering cost is the cost of placing an order for inventory, which includes transportation, administrative, and processing costs. The holding cost is the cost of storing inventory, which includes the cost of capital as well as the cost of space. From the formula above, we see that ordering the higher quantity would bring our inventory costs down to $61,515—a $1,485 savings.

Economic Order Quantity (EOQ) is the order size that minimizes the sum of ordering and holding costs related to raw materials or merchandise inventories. Keeping costs low will inflate margins and ultimately drive more revenue for the company. The Economic Order Quantity (EOQ) is an inventory management system that ensures a company orders the right amount of inventory that meets the demand for the product. Businesses use it as a valuable tool to make decisions about the number of inventory to order and keep, and how often to reorder to attract the lowest possible costs. The advantages of EOQ include reduced ordering and holding costs, while disadvantages include assumptions that may not match real-life conditions. Even though ERP/MRP systems do not automatically calculate the economic order quantity for your stock keeping units, the data collection capacity of such systems could prove very useful in calculating it.

Seasonal changes in demand, for instance, are known to occur for many businesses, and costs can vary over time. The eoq formula must be modified in this scenario when there is a specific order cost. We must substitute “order cost” in the formula to accommodate for each specific cost. The total annual order cost divided by the unit production cost should still be a good indicator of how many units can be ordered during a year before incurring excessive costs. There are so many online Economic Order Quantity (EOQ) calculators you can use to calculate EOQ for your company.